Skiving Machining Center for Gears GMS450

Super accurate high performance skiving at peak of ideals

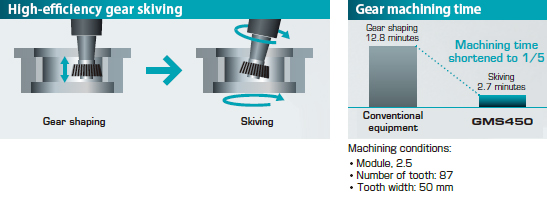

- High efficiency gear skiving reduces machining time to as much as 1/5 (compared to gear shaping)

- Proprietary technologies used to add lathe and drill to skiving machine for a multi-functional gear shaper

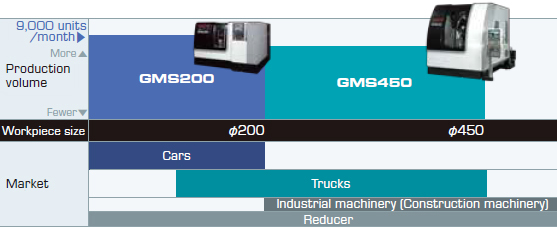

- Both mass production & multi-type-small-lot production

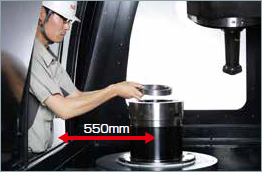

- Compact yet can be machining up to 450mm diameter part

- Hard-skiving achieves high-precision machining of hardened gears

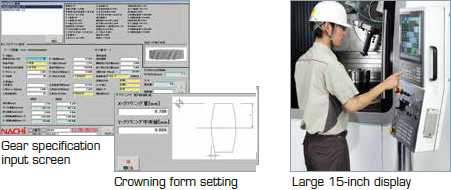

- Interactive operation screen provides excellent man-machine interface

Outline

Main text

Skiving machining center for Gears GMS450

|

Super accurate high performance skiving at peak of ideals

|

Features

Main text

Skiving machining center for Gears GMS450

Reduces machining time to as much as 1/5 (compared to gear shaping)

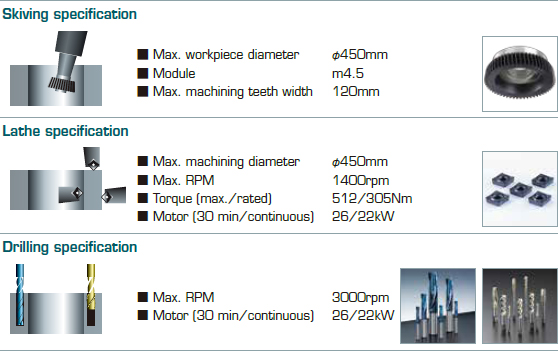

Three jobs consolidated in one machine

Skiving machining center for Gears GMS450 achieves a high-efficiency gear skiving machine.

Plus, it also has lathe and drill functions that integrate jobs in this skiving gear shaping machine.

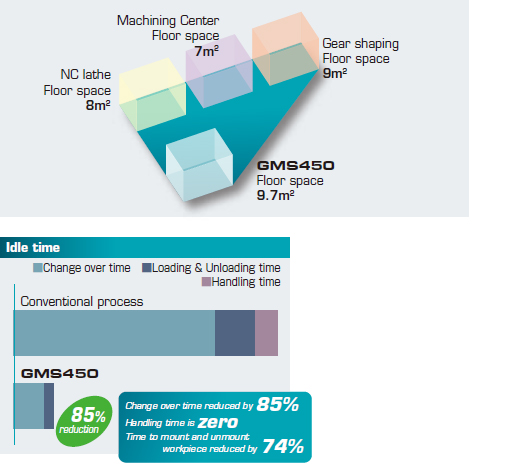

To achieve smart production lines by reducing floor space

Skiving machining center for Gears requires little space to improve gear production lines to be smart production lines that can handle a variety of production formats from multi-type small-lot production to high-volume production.

Proprietary technologies produce new design skiving machine

Upright machining center built with gantry-type column Skiving machine with table that rotates on B-axis

- New spindle designed for skiving

Super-rigid spindle equipped with large diameter bearing and high-torque direct drive motor - All axes have V-rail slides

V-rail slides with superior rigidity and damping used on all sliding surfaces, including the tool spindle. - X axis and B axis equipped with table clamp mechanism

Superior workability and operability

Simple changeover and loading & unloading of workpieces

Easy access to Jig

Machining application

Skiving cutter

Propose our skiving cutter and cutting conditions to match the various workpiece specifications and applications.

Features of NACHI cutters

- Analyzed cutting mechanism with the cutting tool design technology and gear cutting technology that we have developed. Improved precision of machining work and extended tool life.

- Established surface processing technology needed for skiving that produces better surfaces with optimized deposition process and design of coating components.

- Carbide skiving cutters are able to achieve hard skiving process after heat treatment.

Conbination with NACHI robots

NACHI robots combine with machining , washing, deburring, and inspection equipment to produce a fully automated process.

Specifications

Main text

Skiving machining center for Gears GMS450

Main specification

| Machining capacity | Max. workpiece diameter | mm | Ø450 |

|---|---|---|---|

| Max. machining module | — | m4.5 | |

| Max. machining teeth width | mm | 120 | |

| Max. workpiece height | mm | 250 | |

| Gear cutting tool | — | Skiving cutter | |

| Cutter spindle | Spindle taper hole (tool shank type) |

— | 7/24 Taper No.50 (BBT50) |

| Max. RPM of spindle | min-1 | 3000 | |

| Motor (30 min/continuous) | kw | 26/22 | |

| Workpiece spindle | Max. RPM of spindle | min-1 | 1400 |

| Motor (30 min/continuous) | kw | 26/22 | |

| Each unit traverse | Left – Right traverse (X-axis) | mm | 700 |

| Forward – Back traverse (Y-axis) | mm | 350 | |

| Up - Down traverse (Z-axis) | mm | 300 | |

| Tool swivel angle (B-axis) | deg | ±25 | |

| A.T.C. | Number of tool storage | piece | 6 |

| Max. tool diameter | mm | Ø150 | |

| Max. tool length | mm | 250 | |

| Tool selection method | — | Tool storage position fixed / random | |

| NC device | Type | — | FANUC 31i-B |

| Display | — | FANUC PANEL-i | |

| Utilities | Overall power used | kVA | 88 |

| Dimensions of machine | Machine height | mm | 2700 |

| Required floor space (width x depth) |

mm | 2500 x 3860 | |

| Net machine weight (main body) |

kg | 22000 | |

| Options | Workpiece chuck External scale 22 piece ATC Hard machining package Workpiece handling by robots |

||

Layout diagram

Product line-up for ring gear machining

![Nachi America [Home]](/img/NachiAmerica_logo.svg)